Many of the top pharmaceutical contract manufacturers provide the full range of services from pre-formulation work through to manufacturing and packaging. As a pharmaceutical company, it is a good idea to look for a contract development manufacturing organization (CDMO) with this capacity to streamline the development and manufacturing process and include pharmaceutical packaging services.

As there are several companies with this capacity, taking the time to compare options will be important. Different CDMOs will have different services and options available, which can make one or more the ideal choice for specific needs.

Packaging Types

Each type of medication will be suited to one or more options for packaging types. The form of the medication from a capsule or tablet to liquid or semi-solid will impact the types of pharmaceutical packaging services that are best suited for the product.

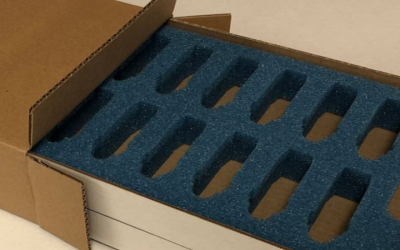

Not all companies are able to offer all types of pharmaceutical packaging solutions. Most companies will provide blister packs, both thermoform and coldform, as well as bottling, all which can be used for tablets and capsules.

Bottling can be completed through fully automated systems, which will typically reduce cost while also allowing for easy scalability of production. The capacity of the CDMO will also be a factor in how fast they can scale up manufacturing and packaging to meet demands. Sachets, or individual packaging of medications in strips or rolls, is also possible.

Bottling of liquids is usually done on automated lines. However, as with bottling of solids, it can also be done manually when required. Many companies are also equipped to produce single dosage syringe applications, something that is more commonly used today than in the past.

Not all pharmaceutical packaging services will provide packaging options for the semi-solids. These creams, ointments and lotion types of formulations are usually packaged in tubes and jars and do require specialized equipment and lines for production.